First impressions are lasting! When I walk into your organization, what impression will you leave? What story do your people tell? What message do they send? Does the story and message align? Do you walk the talk?

Lean organizations never fail to impress me. From the wait time at reception, through the safety orientation and the facility walk through, these organizations have their act together. It’s about caring for people and the total customer experience. Whether the visitor is a customer, a prospective employee, or a tourist, you only have one chance to make that first impression.

What do I notice and look for during that first walk through at a facility? What are the indications that this company has their act together and is on their way to becoming a lean enterprise?

Here is a short list of some tell tale signs;

• Clear signage to guide me through the lot and the visitor parking area to reception.

• The kaizen award parking stall designation near the front door.

• The absence of designated parking by position or status in the organization.

• A friendly greeting by reception, a smile that indicates they enjoy being part of the team and a wait time commitment that reflects respect for me and my time.

• A simple mission, vision and values statement that aligns with posted community involvement and engagement initiatives.

• Transfer of that mission and vision to a posted true north dashboard once inside.

• Communication boards that are current and relevant.

• Team engagement and recognition, photos of team members and success delivered by CI teams.

• Visual display boards at work centers highlighting what takes priority today.

• Work centers arranged to optimize flow.

• Visual indicators for wayfinding, process flow, inventory control and WIP management.

• Stoplight controls for problem awareness and designation of ownership and accountability (who is doing what by when)

• Standard work procedures that are posted.

• Cross training, demonstrated skills and abilities matrix by station.

• Takt time, cycle time and deviation correction indications.

• 5Y problem solving and CI initiatives by workstation.

• A lack of cupboards, drawers and closets to “hide” clutter.

• Batch size and material movement methods.

• An indication that equipment is cleaned and inspected regularly.

• A workforce that is engaged and enthused about their work and the organization. A work team that talks about what they are doing to improve

As I dig deeper into the organization with the leadership, we’ll discuss their metrics, how they are becoming a learning organization and the initiatives underway to build and maintain the culture they envision. We’ll discuss their vision for the future, the coming months and how they are transforming that vision to an action plan for strategic deployment.

In a lean enterprise, I rarely hear “it won’t work here” or “I’ve been meaning to try that”. It seems that excuses get replaced by actions in the world of lean. And that energy is contagious!

Norm

www.normanbain.com

Wednesday, December 30, 2009

Monday, December 14, 2009

Make things happen

Just read an interesting post by Gina Trapani who blogs at http://smarterware.org/ that I thought I'd share here. It speaks to the heart of focused change.

Getting things done is not the same as making things happen.

You can…

…reply to email.

…pay the bills.

…cross off to-do’s.

…fulfill your obligation.

…repeat what you heard.

…go with the flow.

…anticipate roadblocks.

…aim for “good enough.”

Or you can…

…organize a community.

…take a risk.

…set ambitious goals.

…give more than you take.

…change perceptions.

…forge a new path.

…create possibility.

…demand excellence.

Don’t worry too much about getting things done.

Make things happen.

Norm

www.normanbain.com

Getting things done is not the same as making things happen.

You can…

…reply to email.

…pay the bills.

…cross off to-do’s.

…fulfill your obligation.

…repeat what you heard.

…go with the flow.

…anticipate roadblocks.

…aim for “good enough.”

Or you can…

…organize a community.

…take a risk.

…set ambitious goals.

…give more than you take.

…change perceptions.

…forge a new path.

…create possibility.

…demand excellence.

Don’t worry too much about getting things done.

Make things happen.

Norm

www.normanbain.com

Tuesday, December 8, 2009

Strategy and Approach to Value Stream Mapping

What is Value Stream Mapping?

All businesses consist of processes. Processes for purchasing materials, receiving materials, storing materials, modifying materials, making parts, moving parts, assembling parts, packaging parts, verifying parts, shipping parts, creating invoices, receiving payments, keeping score, recruiting talent, rewarding talent, training talent ... the list as endless as the imagination and complexity of the organization.

However, many of these processes do not add value for the customer.

The customer is defined as the person who uses your product or service. Your customer may not particularly care if you have a harassment policy and have everyone trained in its application. Your customer may not see value in the time your team spends waiting for instruction or searching for tools. We can all identify several activities that, if viewed through our customers eyes, would not be considered adding value.

To be considered value added, the activity must meet three conditions; (1) it must be something that the customer would be willing to pay for, (2) it must change the “thing” as it moves through the process, and (3) it must be done right the first time. Rework in any form does not add value.

Value stream mapping looks at the flow of product through your entire process and links together the steps that add value. At each of these steps we determine who is involved involved, the time it takes, the value added time it takes, the inventory of parts and product on hand, the signals and instruction that tell us what and when to build.

A value stream map displays a picture of how material and instructions move product through a value stream. So the first step in creating a value stream map, is identifying the value stream. What product, or family of products are we trying to map?

Key things to consider; What products share common processes? Where does the value stream start and end (order entry to shipment)? Are there optional processes? Does everyone on every shift perform the tasks in the same sequence, using the same equipment and the same procedure? Have we asked the people currently doing the work if this is how they really do it today?

Once the map is complete, it will clearly show how long it takes material to flow through the value stream (our lead time) and some opportunities for improvement will become apparent.

A value stream mapping exercise typically starts with a “scoping exercise”. This exercise looks at each step in the process and identifies;

(1) What is the main activity at this step? What comes in and what goes out?

(2) How long does it take (best time, worst time, average time)?

(3) How much of that time is adding value?

(4) What materials are required, how much do we have, how much do we need?

(5) What is our cue to do work (a schedule, an empty shelf, supervisory instruction)?

(6) How long does it take to set up the equipment/job?

(7) How do we move material into the station and out of the station? What is the cue to move?

To complete the scoping exercise, someone who is familiar with the work performed at this step needs to be present.

Once we have completed the scoping exercise, others working in the area should review the result to ensure nothing was missed or overlooked.

Once each step in the value stream has been identified and documented in the scoping exercise, we can transfer this information to a value stream map. The map will present a picture of how our value steam functions and give some insight into how the process can be improved.

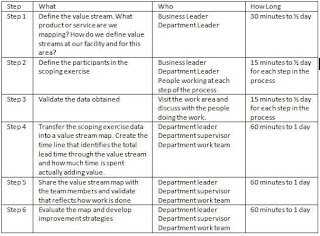

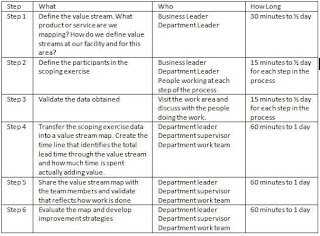

The following steps are required in value stream mapping:

The value stream mapping exercise will clearly show where problems/opportunities exist with material and communication flow through the facility. The leadership of the area along with the work team can use this information to formulate an improvement strategy to improve this flow through the value stream.

Value stream mapping is a powerful tool to provide insight to value stream throughput improvement.

Norm

www.normanbain.com

All businesses consist of processes. Processes for purchasing materials, receiving materials, storing materials, modifying materials, making parts, moving parts, assembling parts, packaging parts, verifying parts, shipping parts, creating invoices, receiving payments, keeping score, recruiting talent, rewarding talent, training talent ... the list as endless as the imagination and complexity of the organization.

However, many of these processes do not add value for the customer.

The customer is defined as the person who uses your product or service. Your customer may not particularly care if you have a harassment policy and have everyone trained in its application. Your customer may not see value in the time your team spends waiting for instruction or searching for tools. We can all identify several activities that, if viewed through our customers eyes, would not be considered adding value.

To be considered value added, the activity must meet three conditions; (1) it must be something that the customer would be willing to pay for, (2) it must change the “thing” as it moves through the process, and (3) it must be done right the first time. Rework in any form does not add value.

Value stream mapping looks at the flow of product through your entire process and links together the steps that add value. At each of these steps we determine who is involved involved, the time it takes, the value added time it takes, the inventory of parts and product on hand, the signals and instruction that tell us what and when to build.

A value stream map displays a picture of how material and instructions move product through a value stream. So the first step in creating a value stream map, is identifying the value stream. What product, or family of products are we trying to map?

Key things to consider; What products share common processes? Where does the value stream start and end (order entry to shipment)? Are there optional processes? Does everyone on every shift perform the tasks in the same sequence, using the same equipment and the same procedure? Have we asked the people currently doing the work if this is how they really do it today?

Once the map is complete, it will clearly show how long it takes material to flow through the value stream (our lead time) and some opportunities for improvement will become apparent.

A value stream mapping exercise typically starts with a “scoping exercise”. This exercise looks at each step in the process and identifies;

(1) What is the main activity at this step? What comes in and what goes out?

(2) How long does it take (best time, worst time, average time)?

(3) How much of that time is adding value?

(4) What materials are required, how much do we have, how much do we need?

(5) What is our cue to do work (a schedule, an empty shelf, supervisory instruction)?

(6) How long does it take to set up the equipment/job?

(7) How do we move material into the station and out of the station? What is the cue to move?

To complete the scoping exercise, someone who is familiar with the work performed at this step needs to be present.

Once we have completed the scoping exercise, others working in the area should review the result to ensure nothing was missed or overlooked.

Once each step in the value stream has been identified and documented in the scoping exercise, we can transfer this information to a value stream map. The map will present a picture of how our value steam functions and give some insight into how the process can be improved.

The following steps are required in value stream mapping:

The value stream mapping exercise will clearly show where problems/opportunities exist with material and communication flow through the facility. The leadership of the area along with the work team can use this information to formulate an improvement strategy to improve this flow through the value stream.

Value stream mapping is a powerful tool to provide insight to value stream throughput improvement.

Norm

www.normanbain.com

Subscribe to:

Posts (Atom)