First impressions are lasting! When I walk into your organization, what impression will you leave? What story do your people tell? What message do they send? Does the story and message align? Do you walk the talk?

Lean organizations never fail to impress me. From the wait time at reception, through the safety orientation and the facility walk through, these organizations have their act together. It’s about caring for people and the total customer experience. Whether the visitor is a customer, a prospective employee, or a tourist, you only have one chance to make that first impression.

What do I notice and look for during that first walk through at a facility? What are the indications that this company has their act together and is on their way to becoming a lean enterprise?

Here is a short list of some tell tale signs;

• Clear signage to guide me through the lot and the visitor parking area to reception.

• The kaizen award parking stall designation near the front door.

• The absence of designated parking by position or status in the organization.

• A friendly greeting by reception, a smile that indicates they enjoy being part of the team and a wait time commitment that reflects respect for me and my time.

• A simple mission, vision and values statement that aligns with posted community involvement and engagement initiatives.

• Transfer of that mission and vision to a posted true north dashboard once inside.

• Communication boards that are current and relevant.

• Team engagement and recognition, photos of team members and success delivered by CI teams.

• Visual display boards at work centers highlighting what takes priority today.

• Work centers arranged to optimize flow.

• Visual indicators for wayfinding, process flow, inventory control and WIP management.

• Stoplight controls for problem awareness and designation of ownership and accountability (who is doing what by when)

• Standard work procedures that are posted.

• Cross training, demonstrated skills and abilities matrix by station.

• Takt time, cycle time and deviation correction indications.

• 5Y problem solving and CI initiatives by workstation.

• A lack of cupboards, drawers and closets to “hide” clutter.

• Batch size and material movement methods.

• An indication that equipment is cleaned and inspected regularly.

• A workforce that is engaged and enthused about their work and the organization. A work team that talks about what they are doing to improve

As I dig deeper into the organization with the leadership, we’ll discuss their metrics, how they are becoming a learning organization and the initiatives underway to build and maintain the culture they envision. We’ll discuss their vision for the future, the coming months and how they are transforming that vision to an action plan for strategic deployment.

In a lean enterprise, I rarely hear “it won’t work here” or “I’ve been meaning to try that”. It seems that excuses get replaced by actions in the world of lean. And that energy is contagious!

Norm

www.normanbain.com

Wednesday, December 30, 2009

Monday, December 14, 2009

Make things happen

Just read an interesting post by Gina Trapani who blogs at http://smarterware.org/ that I thought I'd share here. It speaks to the heart of focused change.

Getting things done is not the same as making things happen.

You can…

…reply to email.

…pay the bills.

…cross off to-do’s.

…fulfill your obligation.

…repeat what you heard.

…go with the flow.

…anticipate roadblocks.

…aim for “good enough.”

Or you can…

…organize a community.

…take a risk.

…set ambitious goals.

…give more than you take.

…change perceptions.

…forge a new path.

…create possibility.

…demand excellence.

Don’t worry too much about getting things done.

Make things happen.

Norm

www.normanbain.com

Getting things done is not the same as making things happen.

You can…

…reply to email.

…pay the bills.

…cross off to-do’s.

…fulfill your obligation.

…repeat what you heard.

…go with the flow.

…anticipate roadblocks.

…aim for “good enough.”

Or you can…

…organize a community.

…take a risk.

…set ambitious goals.

…give more than you take.

…change perceptions.

…forge a new path.

…create possibility.

…demand excellence.

Don’t worry too much about getting things done.

Make things happen.

Norm

www.normanbain.com

Tuesday, December 8, 2009

Strategy and Approach to Value Stream Mapping

What is Value Stream Mapping?

All businesses consist of processes. Processes for purchasing materials, receiving materials, storing materials, modifying materials, making parts, moving parts, assembling parts, packaging parts, verifying parts, shipping parts, creating invoices, receiving payments, keeping score, recruiting talent, rewarding talent, training talent ... the list as endless as the imagination and complexity of the organization.

However, many of these processes do not add value for the customer.

The customer is defined as the person who uses your product or service. Your customer may not particularly care if you have a harassment policy and have everyone trained in its application. Your customer may not see value in the time your team spends waiting for instruction or searching for tools. We can all identify several activities that, if viewed through our customers eyes, would not be considered adding value.

To be considered value added, the activity must meet three conditions; (1) it must be something that the customer would be willing to pay for, (2) it must change the “thing” as it moves through the process, and (3) it must be done right the first time. Rework in any form does not add value.

Value stream mapping looks at the flow of product through your entire process and links together the steps that add value. At each of these steps we determine who is involved involved, the time it takes, the value added time it takes, the inventory of parts and product on hand, the signals and instruction that tell us what and when to build.

A value stream map displays a picture of how material and instructions move product through a value stream. So the first step in creating a value stream map, is identifying the value stream. What product, or family of products are we trying to map?

Key things to consider; What products share common processes? Where does the value stream start and end (order entry to shipment)? Are there optional processes? Does everyone on every shift perform the tasks in the same sequence, using the same equipment and the same procedure? Have we asked the people currently doing the work if this is how they really do it today?

Once the map is complete, it will clearly show how long it takes material to flow through the value stream (our lead time) and some opportunities for improvement will become apparent.

A value stream mapping exercise typically starts with a “scoping exercise”. This exercise looks at each step in the process and identifies;

(1) What is the main activity at this step? What comes in and what goes out?

(2) How long does it take (best time, worst time, average time)?

(3) How much of that time is adding value?

(4) What materials are required, how much do we have, how much do we need?

(5) What is our cue to do work (a schedule, an empty shelf, supervisory instruction)?

(6) How long does it take to set up the equipment/job?

(7) How do we move material into the station and out of the station? What is the cue to move?

To complete the scoping exercise, someone who is familiar with the work performed at this step needs to be present.

Once we have completed the scoping exercise, others working in the area should review the result to ensure nothing was missed or overlooked.

Once each step in the value stream has been identified and documented in the scoping exercise, we can transfer this information to a value stream map. The map will present a picture of how our value steam functions and give some insight into how the process can be improved.

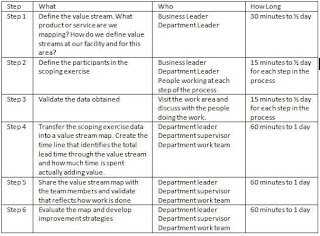

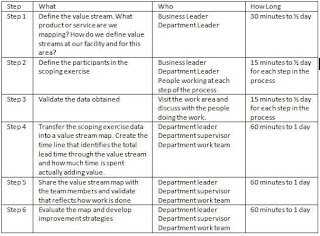

The following steps are required in value stream mapping:

The value stream mapping exercise will clearly show where problems/opportunities exist with material and communication flow through the facility. The leadership of the area along with the work team can use this information to formulate an improvement strategy to improve this flow through the value stream.

Value stream mapping is a powerful tool to provide insight to value stream throughput improvement.

Norm

www.normanbain.com

All businesses consist of processes. Processes for purchasing materials, receiving materials, storing materials, modifying materials, making parts, moving parts, assembling parts, packaging parts, verifying parts, shipping parts, creating invoices, receiving payments, keeping score, recruiting talent, rewarding talent, training talent ... the list as endless as the imagination and complexity of the organization.

However, many of these processes do not add value for the customer.

The customer is defined as the person who uses your product or service. Your customer may not particularly care if you have a harassment policy and have everyone trained in its application. Your customer may not see value in the time your team spends waiting for instruction or searching for tools. We can all identify several activities that, if viewed through our customers eyes, would not be considered adding value.

To be considered value added, the activity must meet three conditions; (1) it must be something that the customer would be willing to pay for, (2) it must change the “thing” as it moves through the process, and (3) it must be done right the first time. Rework in any form does not add value.

Value stream mapping looks at the flow of product through your entire process and links together the steps that add value. At each of these steps we determine who is involved involved, the time it takes, the value added time it takes, the inventory of parts and product on hand, the signals and instruction that tell us what and when to build.

A value stream map displays a picture of how material and instructions move product through a value stream. So the first step in creating a value stream map, is identifying the value stream. What product, or family of products are we trying to map?

Key things to consider; What products share common processes? Where does the value stream start and end (order entry to shipment)? Are there optional processes? Does everyone on every shift perform the tasks in the same sequence, using the same equipment and the same procedure? Have we asked the people currently doing the work if this is how they really do it today?

Once the map is complete, it will clearly show how long it takes material to flow through the value stream (our lead time) and some opportunities for improvement will become apparent.

A value stream mapping exercise typically starts with a “scoping exercise”. This exercise looks at each step in the process and identifies;

(1) What is the main activity at this step? What comes in and what goes out?

(2) How long does it take (best time, worst time, average time)?

(3) How much of that time is adding value?

(4) What materials are required, how much do we have, how much do we need?

(5) What is our cue to do work (a schedule, an empty shelf, supervisory instruction)?

(6) How long does it take to set up the equipment/job?

(7) How do we move material into the station and out of the station? What is the cue to move?

To complete the scoping exercise, someone who is familiar with the work performed at this step needs to be present.

Once we have completed the scoping exercise, others working in the area should review the result to ensure nothing was missed or overlooked.

Once each step in the value stream has been identified and documented in the scoping exercise, we can transfer this information to a value stream map. The map will present a picture of how our value steam functions and give some insight into how the process can be improved.

The following steps are required in value stream mapping:

The value stream mapping exercise will clearly show where problems/opportunities exist with material and communication flow through the facility. The leadership of the area along with the work team can use this information to formulate an improvement strategy to improve this flow through the value stream.

Value stream mapping is a powerful tool to provide insight to value stream throughput improvement.

Norm

www.normanbain.com

Monday, November 23, 2009

In todays economy - why not create your own job?

Do you have a hobby that you absolutely love? Are you an expert at something? If so, you just might be able to turn that hobby into a few extra bucks every month.

I'm sure you've heard that “it’s not work if you love what you do”. In reality, however, most of us are stuck in jobs we don’t love, working for people we don’t respect, and feel we are going no-where fast. We stay, because we are worried about paying the rent and getting out of debt.

Wouldn’t it be great if you could turn what you love to do into your full time job? Time flies when you're having fun — doing what you gladly spend your other 8 hours doing! Why not make money doing that?

Check out Melanie Jordan's book What you know is worth more than you think!

Here are some things to consider:

1. What can you teach? Before you say "nothing", take a moment and really think about this. Take some time to brainstorm your talents, skills and interests. Do you speak another language? Are you a marketing whiz? Have you mastered social networking sites like Twitter or Facebook?

2. What can you do from home? Brand building. Build web sites. Process forms. Do company billing from home.

3. How much can you make? Consultants and teachers can make $100 to $300 an hour! Freelancers can earn $20 - $100 an hour. Not bad for doing something you enjoy.

The list is endless. Limited only by YOUR imagination. Best success . . .

Get started NOW - With the book "What you know is worth more than you think!"

Norm

www.normanbain.com

I'm sure you've heard that “it’s not work if you love what you do”. In reality, however, most of us are stuck in jobs we don’t love, working for people we don’t respect, and feel we are going no-where fast. We stay, because we are worried about paying the rent and getting out of debt.

Wouldn’t it be great if you could turn what you love to do into your full time job? Time flies when you're having fun — doing what you gladly spend your other 8 hours doing! Why not make money doing that?

Check out Melanie Jordan's book What you know is worth more than you think!

Here are some things to consider:

1. What can you teach? Before you say "nothing", take a moment and really think about this. Take some time to brainstorm your talents, skills and interests. Do you speak another language? Are you a marketing whiz? Have you mastered social networking sites like Twitter or Facebook?

2. What can you do from home? Brand building. Build web sites. Process forms. Do company billing from home.

3. How much can you make? Consultants and teachers can make $100 to $300 an hour! Freelancers can earn $20 - $100 an hour. Not bad for doing something you enjoy.

The list is endless. Limited only by YOUR imagination. Best success . . .

Get started NOW - With the book "What you know is worth more than you think!"

Norm

www.normanbain.com

Wednesday, November 18, 2009

The Untold Secret To Lean

The Untold Secret to Whole Business Improvement with Lean Thinking and the Lies you’ve been told about Lean so far!

More companies are becoming frustrated with their efforts to reduce waste and improve profits by implementing lean tools. In this article, we explore the untold secret of Lean and expose why so many companies have failed to deliver the results promised by Lean Thinking.

I’ve been teaching Lean tools for a decade. I was introduced to the tools when I was working as a Tier-1 supplier for Toyota. Before that, I was a proponent of TQM, SPC, and Six Sigma. The tools and foundation of lean thinking has been with me for most of my working career. It was not until I was in my third year as a Lean Consultant that I realized why Lean does not work for many companies. Why they report disappointing results and why the journey to becoming a lean enterprise eludes so many organizations.

Contrary to popular belief, lean thinking is NOT about reducing waste. It is NOT about value through the customer’s eyes, and it is NOT about applying tools on the value stream.

Like many lean practitioners, I got caught up in applying the tools. Identifying the value stream. Eliminating waste. Introducing flow, laying out work cells, implementing kanban, pull and staging kaizen events. In the process, I missed the point. The point that most companies miss. The secret to what makes lean work anywhere.

The tools seem pretty sexy and we get caught up in the buzz about what tool works where. What is the bottleneck process? How can I elevate the constraint? Why I should not try to solve all the problems at once?

Looking back, every book and training presentation I reviewed about lean touched on the secret. But somehow, I missed it. And I’m betting you did too. So here it is, simply and concisely. The “secret” to making lean work anywhere:

Get the rest of this post by clicking here

Norm

www.normanbain.com

More companies are becoming frustrated with their efforts to reduce waste and improve profits by implementing lean tools. In this article, we explore the untold secret of Lean and expose why so many companies have failed to deliver the results promised by Lean Thinking.

I’ve been teaching Lean tools for a decade. I was introduced to the tools when I was working as a Tier-1 supplier for Toyota. Before that, I was a proponent of TQM, SPC, and Six Sigma. The tools and foundation of lean thinking has been with me for most of my working career. It was not until I was in my third year as a Lean Consultant that I realized why Lean does not work for many companies. Why they report disappointing results and why the journey to becoming a lean enterprise eludes so many organizations.

Contrary to popular belief, lean thinking is NOT about reducing waste. It is NOT about value through the customer’s eyes, and it is NOT about applying tools on the value stream.

Like many lean practitioners, I got caught up in applying the tools. Identifying the value stream. Eliminating waste. Introducing flow, laying out work cells, implementing kanban, pull and staging kaizen events. In the process, I missed the point. The point that most companies miss. The secret to what makes lean work anywhere.

The tools seem pretty sexy and we get caught up in the buzz about what tool works where. What is the bottleneck process? How can I elevate the constraint? Why I should not try to solve all the problems at once?

Looking back, every book and training presentation I reviewed about lean touched on the secret. But somehow, I missed it. And I’m betting you did too. So here it is, simply and concisely. The “secret” to making lean work anywhere:

Get the rest of this post by clicking here

Norm

www.normanbain.com

Monday, November 16, 2009

Changing Behaviour

I have been challenged with involvement and compliance in an office waste reduction initiative. In our self assessment study, we identified that meetings and emails demanded 20% of our office workers week. The same self-assessment indicated that 78% of the time for emails and 57% of the time spent in meetings was considered wasted by those who participated.

Regardless of this result, people working in the office were reluctant to rate themselves and provide feedback to each other on what they considered wasteful and how to improve. Third party audits are snapshots in time - we are looking for ways to engage and change the office culture to eliminate waste.

I ran across an interesting approach taken by Barnes-Jewish St. Peters Hospital (BJSPH) in St. Peters, MO. If you have been struggling with the carrot/stick approach to changing behaviour, their model may be of interest. Click here for their approach.

Anyone seeing the results of our self assessment agrees that we are on the right track. What is your experience in changing behaviour to support "doing the right thing".

Norm

www.normanbain.com

Regardless of this result, people working in the office were reluctant to rate themselves and provide feedback to each other on what they considered wasteful and how to improve. Third party audits are snapshots in time - we are looking for ways to engage and change the office culture to eliminate waste.

I ran across an interesting approach taken by Barnes-Jewish St. Peters Hospital (BJSPH) in St. Peters, MO. If you have been struggling with the carrot/stick approach to changing behaviour, their model may be of interest. Click here for their approach.

Anyone seeing the results of our self assessment agrees that we are on the right track. What is your experience in changing behaviour to support "doing the right thing".

Norm

www.normanbain.com

Friday, November 13, 2009

Why do CI tools fail to deliver results.

I had an interesting discussion with a client this morning. We have been talking through his organizational challenges and he was pondering which tool we should be using next.

I received an email from Seth Godin today that struck me following this conversation. Seth’s message was that “to a person with a hammer, every problem seems like a nail”. While I had heard this axiom before, it really hit home today.

Perhaps this is why many people are not seeing the results that they are striving for with their continuous improvement initiatives. Rather than looking at their organization systematically and identifying the opportunities for waste elimination, we look in our toolbox and select which tool to play with next.

With all the focus on tools, we can easily lose perspective on a systems approach. The opportunities in the organization drive the need for the tools. Our understanding of lean thinking helps us select the right tool to apply. We should not be selecting the hammer and go hunting for loose nails.

Perhaps this is a common problem when learning the tools. Perhaps this is why I hear “we tried that before - lean does not work here”. I’d hate to see the doctor for a head cold and be told he recommends surgery, just because he is a surgeon.

Food for thought.

Norm

www.normanbain.com

I received an email from Seth Godin today that struck me following this conversation. Seth’s message was that “to a person with a hammer, every problem seems like a nail”. While I had heard this axiom before, it really hit home today.

Perhaps this is why many people are not seeing the results that they are striving for with their continuous improvement initiatives. Rather than looking at their organization systematically and identifying the opportunities for waste elimination, we look in our toolbox and select which tool to play with next.

With all the focus on tools, we can easily lose perspective on a systems approach. The opportunities in the organization drive the need for the tools. Our understanding of lean thinking helps us select the right tool to apply. We should not be selecting the hammer and go hunting for loose nails.

Perhaps this is a common problem when learning the tools. Perhaps this is why I hear “we tried that before - lean does not work here”. I’d hate to see the doctor for a head cold and be told he recommends surgery, just because he is a surgeon.

Food for thought.

Norm

www.normanbain.com

Monday, November 9, 2009

The Journey to Whole Business Improvement

Why do change management initiatives fall short of the mark after delivering such promising initial success? Why are gains in one area of the business difficult to duplicate in others? Why are many businesses disappointed with the results of their improvement initiative? Why are the concepts of lean manufacturing difficult to apply outside the factory? How can I engage the entire organization in the improvement plan? These are the questions answered in this brief discussion on whole business improvement by applying “Lean Thinking”.

How profitable is your organization? Profit is the lifeblood of business. Every business needs profit. Without it, they will not be in business for long.

This graph from www.p360.org,

shows the typical profit margins for selected industries. Most fall between 1 and 20%.

A company with a 6% profit margin must generate $983,000 in sales to pay for a $59,000 improvement project. Is that what your employees think about when they propose that new computer system?

Most manufacturing operations have a profit margin of less than 8%. While the target gross profit margin is typically much higher (35%), the finance and G&A costs erode that number significantly.

While other industries can generate higher profit margins, we commonly hear the following statements in traditional organizations:

• It takes too long to get products through the process.

• Administration costs are climbing faster than sales.

• We need more people.

• Problems with our products go undetected until our customers are using them.

• Things are fixed, but they don’t stay fixed.

• Our inventory is too high. Yet we don’t have what our customer wants in stock.

• We tried that before. It won’t work here.

• You don’t understand the culture here. That’s not the way we do things. Its different in our industry.

• We have quality teams, continuous improvement teams, ISO programs, re-engineering efforts, balanced scorecards, six sigma trained black belts. Its like the flavour of the month program, yet we are not seeing the results in real numbers.

When you hear the word Lean, what do you think about? “Manufacturing”, is the usual first response. “Lean Manufacturing”. Toyota is the example most often used. Toyota and Cars. Assembly line manufacturing. That’s what most people think Lean is.

Manufacturing is also the first place many people look to implement improvements. Yet manufacturing processes typically account for less than 20% of the total process lead time (the time it takes from when you get a customer order, to when you cash the cheque).

It may seem surprising, but Lean thinking has nothing to do with cars - or manufacturing. It is about eliminating waste and solving problems in processes. Any process.

The challenge with lean is in seeing the problems, identifying the waste.

In most manufacturing operations, only 5% of activities add value for the customer. Adding value means (1) it changes the thing going through the process, (2) the customer is willing to pay for the activity, and (3) it is done right the first time. This implies that 95% of what we do does NOT add value and is potential waste. In offices, the waste is even higher.

Managers and supervisors will only see 2% of the waste.

In office and administrative service environments, supervisors and managers only see 2% of the waste. They are too far removed from the daily work to see the waste.

The people doing the work have learned to live with the waste. They may have created work-arounds in the system to get things done. These, in themselves, add more waste.

What are these unseen wastes? The time it takes to find a document. The extra signature required on an expense statement. The rework on a proposal because the correct template was not used. The time it takes to walk across the building to photocopy a report. A power point presentation made, just in case the boss asks for it. The meeting that does not start on time or runs too long. The manager who “walks the floor” to “see what is going on”.

In a typical office, it is assumed that if people are at their desks and look busy, they are adding value. All seems well, especially if they have a good attitude.

A purchasing person who works hard, never takes breaks and is always helpful will be seen as a stellar employee. The fact that he takes 25% longer to complete the task due to poor training or lack of resources will be overlooked.

When we apply Lean Thinking in an organization, we look at how we do the work, how the system can be improved, what waste we can find and eliminate. Its not about the person doing the work - whether they are a “good worker” or not. Its about improving the work methods, standardizing processes, providing training and increasing skills.

Lean thinking is about is solving problems, elegantly, with innovation

Learning to identify and eliminate waste is fundamental to lean thinking. We must learn to see waste, and systematically eliminate it.

Thinking of problems as opportunities is not something we are trained to do. With lean, we need to learn to treasure problems - celebrate finding them – this is our opportunity to improve!

Once we clearly see the problem, the root cause must be identified. This requires some structured problem solving. We need to avoid treating the symptoms. Unless we identify the true root cause, the problem will re-occur.

Once the problem and its root cause is clearly understood, we can create solutions. An elegant solution can be a single tiny idea that changes everything. Quite often, this solution is not spending capital.

An elegant solution is one in which the desired effect is achieved, with the least amount of effort. John W. Gardner, the former US Secretary of Health, Education, and Welfare, once said, "We are continually faced with a series of great opportunities brilliantly disguised as insolvable problems."

Elegant solutions are not obvious, except in retrospect.

Organizational Change.

Leaders like silver bullets. Take this tool, transplant it to my organization and everything will be magically fixed.

That’s the flavour of the month.

We end up with so many tools and initiatives underway that we can’t support them all. We keep dropping the ball.

Lean requires a more systematic approach. It has some well known tools to use, but requires discipline, structure and mentoring to make it work. This is why so many organizations report they are disappointed with their lean initiative results. The tools are applied without the systematic approach. “Lean does not work here”, they say.

A flaw with Lean is in the tools themselves. They are simple and when observed in the factory, they seem like common sense. So leaders take the tools from the plant floor and transplant them on their office or service organization. They don’t transplant easily. I don’t see accountants and engineers respond well to tape outlines for their stapler and keyboard.

Truth be known, Lean Thinking works anywhere. Health care, offices, engineering design, sales teams, construction projects, mining industries. Anywhere work gets done, Lean Thinking can be applied. However, it takes a strategic and systematic approach to be successful.

How do I do that?

Working on how we do the work.

A key limitation of traditional improvement initiatives is that they focus on ...

Click here to download the rest of this article.

Norm

www.normanbain.com

How profitable is your organization? Profit is the lifeblood of business. Every business needs profit. Without it, they will not be in business for long.

This graph from www.p360.org,

shows the typical profit margins for selected industries. Most fall between 1 and 20%.

A company with a 6% profit margin must generate $983,000 in sales to pay for a $59,000 improvement project. Is that what your employees think about when they propose that new computer system?

Most manufacturing operations have a profit margin of less than 8%. While the target gross profit margin is typically much higher (35%), the finance and G&A costs erode that number significantly.

While other industries can generate higher profit margins, we commonly hear the following statements in traditional organizations:

• It takes too long to get products through the process.

• Administration costs are climbing faster than sales.

• We need more people.

• Problems with our products go undetected until our customers are using them.

• Things are fixed, but they don’t stay fixed.

• Our inventory is too high. Yet we don’t have what our customer wants in stock.

• We tried that before. It won’t work here.

• You don’t understand the culture here. That’s not the way we do things. Its different in our industry.

• We have quality teams, continuous improvement teams, ISO programs, re-engineering efforts, balanced scorecards, six sigma trained black belts. Its like the flavour of the month program, yet we are not seeing the results in real numbers.

When you hear the word Lean, what do you think about? “Manufacturing”, is the usual first response. “Lean Manufacturing”. Toyota is the example most often used. Toyota and Cars. Assembly line manufacturing. That’s what most people think Lean is.

Manufacturing is also the first place many people look to implement improvements. Yet manufacturing processes typically account for less than 20% of the total process lead time (the time it takes from when you get a customer order, to when you cash the cheque).

It may seem surprising, but Lean thinking has nothing to do with cars - or manufacturing. It is about eliminating waste and solving problems in processes. Any process.

The challenge with lean is in seeing the problems, identifying the waste.

In most manufacturing operations, only 5% of activities add value for the customer. Adding value means (1) it changes the thing going through the process, (2) the customer is willing to pay for the activity, and (3) it is done right the first time. This implies that 95% of what we do does NOT add value and is potential waste. In offices, the waste is even higher.

Managers and supervisors will only see 2% of the waste.

In office and administrative service environments, supervisors and managers only see 2% of the waste. They are too far removed from the daily work to see the waste.

The people doing the work have learned to live with the waste. They may have created work-arounds in the system to get things done. These, in themselves, add more waste.

What are these unseen wastes? The time it takes to find a document. The extra signature required on an expense statement. The rework on a proposal because the correct template was not used. The time it takes to walk across the building to photocopy a report. A power point presentation made, just in case the boss asks for it. The meeting that does not start on time or runs too long. The manager who “walks the floor” to “see what is going on”.

In a typical office, it is assumed that if people are at their desks and look busy, they are adding value. All seems well, especially if they have a good attitude.

A purchasing person who works hard, never takes breaks and is always helpful will be seen as a stellar employee. The fact that he takes 25% longer to complete the task due to poor training or lack of resources will be overlooked.

When we apply Lean Thinking in an organization, we look at how we do the work, how the system can be improved, what waste we can find and eliminate. Its not about the person doing the work - whether they are a “good worker” or not. Its about improving the work methods, standardizing processes, providing training and increasing skills.

Lean thinking is about is solving problems, elegantly, with innovation

Learning to identify and eliminate waste is fundamental to lean thinking. We must learn to see waste, and systematically eliminate it.

Thinking of problems as opportunities is not something we are trained to do. With lean, we need to learn to treasure problems - celebrate finding them – this is our opportunity to improve!

Once we clearly see the problem, the root cause must be identified. This requires some structured problem solving. We need to avoid treating the symptoms. Unless we identify the true root cause, the problem will re-occur.

Once the problem and its root cause is clearly understood, we can create solutions. An elegant solution can be a single tiny idea that changes everything. Quite often, this solution is not spending capital.

An elegant solution is one in which the desired effect is achieved, with the least amount of effort. John W. Gardner, the former US Secretary of Health, Education, and Welfare, once said, "We are continually faced with a series of great opportunities brilliantly disguised as insolvable problems."

Elegant solutions are not obvious, except in retrospect.

Organizational Change.

Leaders like silver bullets. Take this tool, transplant it to my organization and everything will be magically fixed.

That’s the flavour of the month.

We end up with so many tools and initiatives underway that we can’t support them all. We keep dropping the ball.

Lean requires a more systematic approach. It has some well known tools to use, but requires discipline, structure and mentoring to make it work. This is why so many organizations report they are disappointed with their lean initiative results. The tools are applied without the systematic approach. “Lean does not work here”, they say.

A flaw with Lean is in the tools themselves. They are simple and when observed in the factory, they seem like common sense. So leaders take the tools from the plant floor and transplant them on their office or service organization. They don’t transplant easily. I don’t see accountants and engineers respond well to tape outlines for their stapler and keyboard.

Truth be known, Lean Thinking works anywhere. Health care, offices, engineering design, sales teams, construction projects, mining industries. Anywhere work gets done, Lean Thinking can be applied. However, it takes a strategic and systematic approach to be successful.

How do I do that?

Working on how we do the work.

A key limitation of traditional improvement initiatives is that they focus on ...

Click here to download the rest of this article.

Norm

www.normanbain.com

Monday, November 2, 2009

Trust, Respect and Integrity

People say you can't do business with friends and family. They strongly caution against it. They say it is a recipe for disaster.

I say this is a fallacy. My business is built on relationships. The majority of my business comes through my network of contacts. Through the business relationship we become friends and referrals follow. The key is mutual Trust, Respect and Integrity.

I've been doing a great deal of work on the topic of Lean Communication. Through my association with OEM Consultants, I have been working with groups to understand and build on this model of 100% trust and 100% respect. While I'm discovering this communication model, I'm learning that lean communication is not easy or simple. Its tough to communicate clearly, with few words and no assumptions. I know what happens when I assume things ... I make an ASS of U and ME. Yet assumptions continue to be prevalent in my life and my discussions, as I'm sure you experience in yours.

I was taught that trust and respect is earned. I preached that mindset to my kids. My professional experience has shown that there are people who will benefit from my action and ideas to my own detriment. I've discovered that this belief is one reason why change is resisted in organizations. Who will get the credit? I've also learned that this is not the norm. Most do not react this way.

If you are building a team that will effect change in an organization, you must understand the organizational culture. You must build accountability into the team. And that demands mutual trust, respect and accountability.

I started my career in management when teams were all the rage. Individual effort was ignored and individual recognition was discouraged. There is no "I" in "Team". I began to speak in terms of we, rather that I. So much so, that I once had a recruiter ask me exactly what my involvement was in an important improvement project I was describing. I had led the project and driven the results, but had been programmed to talk in terms of "we", not "I".

Times have changed. We live in an age of perceived "entitlement". People tend to think the world owes them something, yet they are not accountable for anything. Perhaps we lost that accountability by focusing on teams. Who, exactly, is "we" when the team work is not done.

There may not be an "I" in team, but there is a "me" if you look for it. Part of lean communication is understanding my responsibility, accepting that responsibility and being accountable for delivering in my role on the team.

I'm coming to understand that lean communication may be the foundation for lean thinking. If we can communicate more effectively, we drive out waste. That is a key principal in lean thinking. And lean thinking can be applied to manufacturing, health care, offices, design houses or any business model.

Lean communication starts on a foundation of trust and respect. Without trust and respect we lose accountability. We lose integrity. And without accountability and integrity we miss the results. So becoming a practitioner of lean communication my be a great foundation to becoming a lean organization.

This foundation of trust, respect and integrity is what makes friendships and family work so well. We don't betray that foundation with family or friends. So why do we in business?

If you would like to learn more about lean communications, contact George at OEM Consultants. Its a different approach. I'm finding it effective. I think its fascinating. I have a lot to learn before I become a lean communicator.

Norm

www.normanbain.com

For more information, see my post on Leadership and Self Deception

I say this is a fallacy. My business is built on relationships. The majority of my business comes through my network of contacts. Through the business relationship we become friends and referrals follow. The key is mutual Trust, Respect and Integrity.

I've been doing a great deal of work on the topic of Lean Communication. Through my association with OEM Consultants, I have been working with groups to understand and build on this model of 100% trust and 100% respect. While I'm discovering this communication model, I'm learning that lean communication is not easy or simple. Its tough to communicate clearly, with few words and no assumptions. I know what happens when I assume things ... I make an ASS of U and ME. Yet assumptions continue to be prevalent in my life and my discussions, as I'm sure you experience in yours.

I was taught that trust and respect is earned. I preached that mindset to my kids. My professional experience has shown that there are people who will benefit from my action and ideas to my own detriment. I've discovered that this belief is one reason why change is resisted in organizations. Who will get the credit? I've also learned that this is not the norm. Most do not react this way.

If you are building a team that will effect change in an organization, you must understand the organizational culture. You must build accountability into the team. And that demands mutual trust, respect and accountability.

I started my career in management when teams were all the rage. Individual effort was ignored and individual recognition was discouraged. There is no "I" in "Team". I began to speak in terms of we, rather that I. So much so, that I once had a recruiter ask me exactly what my involvement was in an important improvement project I was describing. I had led the project and driven the results, but had been programmed to talk in terms of "we", not "I".

Times have changed. We live in an age of perceived "entitlement". People tend to think the world owes them something, yet they are not accountable for anything. Perhaps we lost that accountability by focusing on teams. Who, exactly, is "we" when the team work is not done.

There may not be an "I" in team, but there is a "me" if you look for it. Part of lean communication is understanding my responsibility, accepting that responsibility and being accountable for delivering in my role on the team.

I'm coming to understand that lean communication may be the foundation for lean thinking. If we can communicate more effectively, we drive out waste. That is a key principal in lean thinking. And lean thinking can be applied to manufacturing, health care, offices, design houses or any business model.

Lean communication starts on a foundation of trust and respect. Without trust and respect we lose accountability. We lose integrity. And without accountability and integrity we miss the results. So becoming a practitioner of lean communication my be a great foundation to becoming a lean organization.

This foundation of trust, respect and integrity is what makes friendships and family work so well. We don't betray that foundation with family or friends. So why do we in business?

If you would like to learn more about lean communications, contact George at OEM Consultants. Its a different approach. I'm finding it effective. I think its fascinating. I have a lot to learn before I become a lean communicator.

Norm

www.normanbain.com

For more information, see my post on Leadership and Self Deception

Sunday, November 1, 2009

An on-line 5-why problem solving tool

I have had several questions come my way lately about how 5-why can work as an effective tool for problem solving. I explored this topic on this blog at this post in the past.

I thought it might be fun to create a tool to manage the 5-why process for team problem solving on-line. I could not find one, so I built a 5-why problem solving website. Its free for anyone who wants to try it.

You can explore it by adding a problem here:

http://www.leanjourney.ca/5Why/5why.php

To explore the 5-why example in the earlier post click below:

http://www.leanjourney.ca/5Why/problemsolve.php?qid=1&qcode=uocz3vae

Have fun!

Norm

www.normanbain.com

I thought it might be fun to create a tool to manage the 5-why process for team problem solving on-line. I could not find one, so I built a 5-why problem solving website. Its free for anyone who wants to try it.

You can explore it by adding a problem here:

http://www.leanjourney.ca/5Why/5why.php

To explore the 5-why example in the earlier post click below:

http://www.leanjourney.ca/5Why/problemsolve.php?qid=1&qcode=uocz3vae

Have fun!

Norm

www.normanbain.com

Wednesday, October 28, 2009

Making my website work

Recently, I’ve had an increasing number of discussions with clients who are VERY dissatisfied with their websites. This seems to be a continuing theme as more people develop their on-line presence. What prompted this blog, however, was an email I received about how bad this situation has become. Kate was PISSED OFF to say the least about web designers who create “award winning” sites that cost huge amounts of money and do nothing for the business owner – no measurable improvement in business from being on-line.

A web site should be your online calling card. It should NOT be a status symbol. It should bring in business and MAKE money for you. Is YOUR website doing that for you?

Kate went on to say that the web designers she contacted did not even discuss SEO, keyword placement, traffic, conversion etc. When I discussed these things with her, she was genuinely shocked – the designers she talked to apparently gave this little or NO consideration. Just a pretty site with some cool flash animations.

Before you take the plunge and create a website, be sure to give consideration to what you want your website to do. In particular, give serious consideration to what your CUSTOMERS want from your website.

For more information, download my free ebook, how to make your website work as hard as you do!

Best Success

Norm Bain

www.normanbain.com

Contact Me

A web site should be your online calling card. It should NOT be a status symbol. It should bring in business and MAKE money for you. Is YOUR website doing that for you?

Kate went on to say that the web designers she contacted did not even discuss SEO, keyword placement, traffic, conversion etc. When I discussed these things with her, she was genuinely shocked – the designers she talked to apparently gave this little or NO consideration. Just a pretty site with some cool flash animations.

Before you take the plunge and create a website, be sure to give consideration to what you want your website to do. In particular, give serious consideration to what your CUSTOMERS want from your website.

For more information, download my free ebook, how to make your website work as hard as you do!

Best Success

Norm Bain

www.normanbain.com

Contact Me

Friday, October 16, 2009

Lean Product Development

Thinking Lean is usually associated with manufacturing processes. Many people lose sight of how to apply lean concepts outside the manufacturing plant floor. Articles and case studies are readily available to assist someone starting their lean journey in manufacturing. Not so much is available for those in office environments, accounting departments, engineering teams or in service industries like health care.

While this blog post is geared toward lean product development (concept, design, engineering, production readiness), it applies to lean thinking in many venues. It may provide some insight on how to approach your lean journey.

How would you feel if you reduced your product design cycle by 50%. Kudos all around! How would you react if you were tasked by your boss to deliver your next design project to the market in half the time. How would you approach this challenge? These are the results that design teams are achieving through lean product development. Read on to discover how you can apply these tools in your facility.

In applying lean to the product development process, there are six key issues to explore; focus, clarity, alignment, ideation, WIFM and strategy. We’ll briefly explore each.

Focus

Lean thinking demands we develop our skill in identifying and eliminating waste. We focus our effort on the value stream – the things that provide value for our customer. In office environments, waste manifests itself in several forms. The two most common are distractions and lack of coordination.

Distractions come in the form of interruptions. People requiring assistance, problems that arise, email and spam, letters and correspondence. Each of these place demands on our time – and the result is time, our most precious resource, is wasted. Consistently, in time studies, 60-70% of our day is spent on activities that do not add value to the customer in the product development process. We’re too busy fighting fires.

Lack of coordination translates directly to rework. Priorities change, steps are missed, specifications change, the customer requirements shift. Typically meetings are twice as long as they need to be and have the wrong people at the table. Several people in a typical meeting room do not contribute to the discussion and distract others by texting away on their blackberries. The people who should be in the room are too busy to show up and do not send updates or designates. Meetings don’t start on time and consistently run overtime.

In fact, the first step in improving lead time for product development is waste elimination through time management and communication. Meeting rules, email rules, 5S for the office cubicle, standup coordination meetings and dedicated time for project work are a good place to start.

Clarity

The workplace is a social experience. Many people love to tell stories and debate trivial or low priority points or tasks. Some people spend more time figuring out how not to do something than it would take to just get it done.

Communication in all forms should be clear, concise and to the point. Verification that the intended message was received and understood is essential. The social media site Twitter is a lesson in showing us how to be concise. Summarize your message in just a few lines, and link me to more information if I need it. Tell your story in the subject line of your email – then I don’t even have to open it! When we get good at shortening our message, we don’t have to use the kids acronym language to convey our message. We just become more thoughtful and concise – we think about the customer, the reader, and how they will interpret our message.

Developing lean communication skills should become a priority for your team – and like any skill it must be learned and developed through practice. Develop a safe feedback method to identify and correct team member undesired behaviour and provide tools for your team to measure progress as they improve.

Alignment

In many organizations the structure of the design team itself leads to inefficiencies. Most designers have several bosses and many projects underway simultaneously. While most of us believe we are good multi-taskers, in reality few of us are. We struggle to move each project forward at the same time and all projects are delayed as a result. Traditional design houses are organized by function. This creates its own problems with islands of expertise – similar to departments in manufacturing. Ideally, the organization should be re-arranged by value stream (work flow through cells). In practice, a matrix organization typically develops and this creates its own unique challenges.

Utilize visual management tools focussed on project deliverables to align your team. Toyota’s Oobeya (the big project room) is a great model for this. While many companies do not have the resources to create this type of focussed room, the tools of this model can be readily applied. Use the lean moto “borrow with pride” or “steal shamelessly”. Where you see a good idea that will make you more effective – use it!

Oobeya starts with a model, a visual representation of what we are building to ground the team, focus on the customer and facilitate Quick Problem Solving (QPS). Out of the model flows a graphic representation of the project objectives with links to the corporate strategy or larger project plan. From the objectives, the expected outcomes are displayed and reported along with any urgent issues. From the expected outcomes, the team develops metrics to measure performance and report progress using a Red/Green stoplight approach. Quality, cost and project timing are all included so the team gets a full picture of project status. Next to the metrics, a project schedule defines deliverables by department. This is broken down on a decomposition board to schedule items requiring urgent attention more closely. Issues are clearly posted, whether they are potential or real and the resolution is displayed for communication of lessons learned. From the issues board, an escalated items area is dedicated to issues that require involvement from outside the team, typically decisions by management. The room reads like a storyboard and tells the story at a glance of how the project is progressing as well as how the team is identifying and dealing with issues.

Adopting just a few of these visual tools in your project area will help align your team and smooth the work flow.

What’s In It For Me (WIFM)

Surprisingly, for people not regularly exposed to design teams and engineering professionals, accountability can be a real problem. As professionals we think we know how to manage our projects effectively and do not react well to feedback on performance. Managers tend to step back and let the team work the black box magic that it takes to create the design. Delays and missed project milestones result.

So how do we instil accountability in an organization? Typically, it starts with clarification of roles and responsibilities. Everyone must understand what they are responsible for in terms of expertise, deliverables and timelines. The players themselves must determine how they are going to approach and deliver their tasks on time. The leader asks questions to assure themselves that the expertise and approach will deliver the desired result. Ease off the questioning and pressure as they “get it” and provide positive feedback as results are delivered. This coaching approach will instil accountability and earned trust in the organization.

Transforming the culture of an organization is a never ending and primary task for the leadership. Re-enforcing desired behaviour through constructive feedback is key. If you have read Leadership and Self Deception (Berrett-Koehler Publishers) you will identify with being “out of the box” when you do this to be effective.

Ideation

Ideation is the process for forming ideas or images. Using lean visual management and story boards in the product development area to generate and capture ideas, solutions and improvements will yield surprising results. The creativity and collaboration possible with visual problem solving continues to amaze me. When used with creative teams, the results are impressive. Get out of the cubicle and get some group think happening.

Approach

So what is the approach to implementing lean product development? Where do I start?

Lean’s PDCA cycle is a great model to follow. Start with an assessment of where you are – how lean are you and what are the wastes. A day in the life of your team member is a great place to start.

Once the status of lean in your group has been established, identify the top wastes to be addressed and provide an introductory orientation/training session for the team. Starting with lean communications is appropriate in most design teams.

As you implement the corrective action ideas, pay close attention to what the team is saying. This will give you clues of where to dig for more wastes. Have the team validate and prioritize your list and you have their commitment to proceed with implementation.

Continue this Plan-Do-Check-Act cycle and you’ll soon be mapping processes, validating data and becoming lean.

Learning as you go is the best way. Lean is a journey, not a destination.

Norm

www.normanbain.com

While this blog post is geared toward lean product development (concept, design, engineering, production readiness), it applies to lean thinking in many venues. It may provide some insight on how to approach your lean journey.

How would you feel if you reduced your product design cycle by 50%. Kudos all around! How would you react if you were tasked by your boss to deliver your next design project to the market in half the time. How would you approach this challenge? These are the results that design teams are achieving through lean product development. Read on to discover how you can apply these tools in your facility.

In applying lean to the product development process, there are six key issues to explore; focus, clarity, alignment, ideation, WIFM and strategy. We’ll briefly explore each.

Focus

Lean thinking demands we develop our skill in identifying and eliminating waste. We focus our effort on the value stream – the things that provide value for our customer. In office environments, waste manifests itself in several forms. The two most common are distractions and lack of coordination.

Distractions come in the form of interruptions. People requiring assistance, problems that arise, email and spam, letters and correspondence. Each of these place demands on our time – and the result is time, our most precious resource, is wasted. Consistently, in time studies, 60-70% of our day is spent on activities that do not add value to the customer in the product development process. We’re too busy fighting fires.

Lack of coordination translates directly to rework. Priorities change, steps are missed, specifications change, the customer requirements shift. Typically meetings are twice as long as they need to be and have the wrong people at the table. Several people in a typical meeting room do not contribute to the discussion and distract others by texting away on their blackberries. The people who should be in the room are too busy to show up and do not send updates or designates. Meetings don’t start on time and consistently run overtime.

In fact, the first step in improving lead time for product development is waste elimination through time management and communication. Meeting rules, email rules, 5S for the office cubicle, standup coordination meetings and dedicated time for project work are a good place to start.

Clarity

The workplace is a social experience. Many people love to tell stories and debate trivial or low priority points or tasks. Some people spend more time figuring out how not to do something than it would take to just get it done.

Communication in all forms should be clear, concise and to the point. Verification that the intended message was received and understood is essential. The social media site Twitter is a lesson in showing us how to be concise. Summarize your message in just a few lines, and link me to more information if I need it. Tell your story in the subject line of your email – then I don’t even have to open it! When we get good at shortening our message, we don’t have to use the kids acronym language to convey our message. We just become more thoughtful and concise – we think about the customer, the reader, and how they will interpret our message.

Developing lean communication skills should become a priority for your team – and like any skill it must be learned and developed through practice. Develop a safe feedback method to identify and correct team member undesired behaviour and provide tools for your team to measure progress as they improve.

Alignment

In many organizations the structure of the design team itself leads to inefficiencies. Most designers have several bosses and many projects underway simultaneously. While most of us believe we are good multi-taskers, in reality few of us are. We struggle to move each project forward at the same time and all projects are delayed as a result. Traditional design houses are organized by function. This creates its own problems with islands of expertise – similar to departments in manufacturing. Ideally, the organization should be re-arranged by value stream (work flow through cells). In practice, a matrix organization typically develops and this creates its own unique challenges.

Utilize visual management tools focussed on project deliverables to align your team. Toyota’s Oobeya (the big project room) is a great model for this. While many companies do not have the resources to create this type of focussed room, the tools of this model can be readily applied. Use the lean moto “borrow with pride” or “steal shamelessly”. Where you see a good idea that will make you more effective – use it!

Oobeya starts with a model, a visual representation of what we are building to ground the team, focus on the customer and facilitate Quick Problem Solving (QPS). Out of the model flows a graphic representation of the project objectives with links to the corporate strategy or larger project plan. From the objectives, the expected outcomes are displayed and reported along with any urgent issues. From the expected outcomes, the team develops metrics to measure performance and report progress using a Red/Green stoplight approach. Quality, cost and project timing are all included so the team gets a full picture of project status. Next to the metrics, a project schedule defines deliverables by department. This is broken down on a decomposition board to schedule items requiring urgent attention more closely. Issues are clearly posted, whether they are potential or real and the resolution is displayed for communication of lessons learned. From the issues board, an escalated items area is dedicated to issues that require involvement from outside the team, typically decisions by management. The room reads like a storyboard and tells the story at a glance of how the project is progressing as well as how the team is identifying and dealing with issues.

Adopting just a few of these visual tools in your project area will help align your team and smooth the work flow.

What’s In It For Me (WIFM)

Surprisingly, for people not regularly exposed to design teams and engineering professionals, accountability can be a real problem. As professionals we think we know how to manage our projects effectively and do not react well to feedback on performance. Managers tend to step back and let the team work the black box magic that it takes to create the design. Delays and missed project milestones result.

So how do we instil accountability in an organization? Typically, it starts with clarification of roles and responsibilities. Everyone must understand what they are responsible for in terms of expertise, deliverables and timelines. The players themselves must determine how they are going to approach and deliver their tasks on time. The leader asks questions to assure themselves that the expertise and approach will deliver the desired result. Ease off the questioning and pressure as they “get it” and provide positive feedback as results are delivered. This coaching approach will instil accountability and earned trust in the organization.

Transforming the culture of an organization is a never ending and primary task for the leadership. Re-enforcing desired behaviour through constructive feedback is key. If you have read Leadership and Self Deception (Berrett-Koehler Publishers) you will identify with being “out of the box” when you do this to be effective.

Ideation

Ideation is the process for forming ideas or images. Using lean visual management and story boards in the product development area to generate and capture ideas, solutions and improvements will yield surprising results. The creativity and collaboration possible with visual problem solving continues to amaze me. When used with creative teams, the results are impressive. Get out of the cubicle and get some group think happening.

Approach

So what is the approach to implementing lean product development? Where do I start?

Lean’s PDCA cycle is a great model to follow. Start with an assessment of where you are – how lean are you and what are the wastes. A day in the life of your team member is a great place to start.

Once the status of lean in your group has been established, identify the top wastes to be addressed and provide an introductory orientation/training session for the team. Starting with lean communications is appropriate in most design teams.

As you implement the corrective action ideas, pay close attention to what the team is saying. This will give you clues of where to dig for more wastes. Have the team validate and prioritize your list and you have their commitment to proceed with implementation.

Continue this Plan-Do-Check-Act cycle and you’ll soon be mapping processes, validating data and becoming lean.

Learning as you go is the best way. Lean is a journey, not a destination.

Norm

www.normanbain.com

Thursday, October 15, 2009

Innovators and Integrators

I read an interesting blog from Steve Shapiro through a link in his newsletter that I thought I'd share here. What struck me most was the frame of reference as integrators and innovators. It re-enforces and expands the 5-why concept;

“(As innovators,) we are architects of companies and industries. An architect is not a ‘reengineer.’ To illustrate this point, I often ask clients what is the difference between an optimist, a pessimist, a reengineering consultant, and an architect. The optimist looks at a half filled glass of water and sees it as half-full. The pessimist looks at the same glass and sees it as half-empty. The reengineering consultant sees too much glass. Cut off the top. Downsize. An architect looks at the same glass and asks questions such as ‘Who’s thirsty?’ ‘Why water?’ Or ‘Is there another way to satisfy the thirst?’ It is this questioning, challenging and rethinking that differentiates architects from those who rearrange the deck chairs on The Titanic.”

Find solutions everywhere. Embrace open innovation. And think like an architect. Ask the difficult questions. Assess what matters most. And build a core competency around integrating point solutions.

Read the entire blog post here

Norm

www.normanbain.com

“(As innovators,) we are architects of companies and industries. An architect is not a ‘reengineer.’ To illustrate this point, I often ask clients what is the difference between an optimist, a pessimist, a reengineering consultant, and an architect. The optimist looks at a half filled glass of water and sees it as half-full. The pessimist looks at the same glass and sees it as half-empty. The reengineering consultant sees too much glass. Cut off the top. Downsize. An architect looks at the same glass and asks questions such as ‘Who’s thirsty?’ ‘Why water?’ Or ‘Is there another way to satisfy the thirst?’ It is this questioning, challenging and rethinking that differentiates architects from those who rearrange the deck chairs on The Titanic.”

Find solutions everywhere. Embrace open innovation. And think like an architect. Ask the difficult questions. Assess what matters most. And build a core competency around integrating point solutions.

Read the entire blog post here

Norm

www.normanbain.com

Wednesday, October 14, 2009

Business problems show up as inventory

Have you heard the business axiom "business problems show up as inventory"?

Whether you count inventory as WIP, raw materials or finished goods, the health of your organization is generally apparent in the level of inventory on hand. Many companies recognize this simple truth and adopt a goal to reduce inventories. The senior leadership typically sets a target for a 20% inventory reduction. Most companies typically carry 30-40% more inventory than they need to.

But without effective tools to identify excess inventory and properly manage it, most companies fail to achieve and, more importantly, sustain this inventory reduction goal. The impact of poor sales and operations planning, poor scheduling, engineering changes, material shortages, long lead times and cycle times, batching and large order quantities, overzealous buying and early material receipts are often blamed as causes for excess inventory. Without a structured approach, sustained inventory optimization is difficult to achieve.

Many companies have applied ABC categorization of inventory. This time tested approach states that by paying attention to a small percentage of line items in your inventory (20%), you can manage the lion's share (80%) of your inventory value. Most MRP systems are based on this premise.

The next step in achieving inventory reduction (as a focussed initiative unto itself) is to use the IQR methodology. Inventory Quality Ratio (IQR) is a ratio of your high moving items to the total inventory value. This is typically 30-40% in most companies. By further categorizing your inventory into active, excess, slow moving and non-moving inventory, you can improve this quality ratio enormously - typically identifying, achieving and sustaining a 30% reduction in inventory on hand.

While Lean Thinking as a strategy will yield impressive results in WIP and inventory reduction, the results can take from 6 to 18 months to see. Using IQR as a tool for rapid inventory reduction deployment, expect to see step change results in 3-6 months. Contact us for more details.

Norm

www.normanbain.com

Whether you count inventory as WIP, raw materials or finished goods, the health of your organization is generally apparent in the level of inventory on hand. Many companies recognize this simple truth and adopt a goal to reduce inventories. The senior leadership typically sets a target for a 20% inventory reduction. Most companies typically carry 30-40% more inventory than they need to.

But without effective tools to identify excess inventory and properly manage it, most companies fail to achieve and, more importantly, sustain this inventory reduction goal. The impact of poor sales and operations planning, poor scheduling, engineering changes, material shortages, long lead times and cycle times, batching and large order quantities, overzealous buying and early material receipts are often blamed as causes for excess inventory. Without a structured approach, sustained inventory optimization is difficult to achieve.

Many companies have applied ABC categorization of inventory. This time tested approach states that by paying attention to a small percentage of line items in your inventory (20%), you can manage the lion's share (80%) of your inventory value. Most MRP systems are based on this premise.

The next step in achieving inventory reduction (as a focussed initiative unto itself) is to use the IQR methodology. Inventory Quality Ratio (IQR) is a ratio of your high moving items to the total inventory value. This is typically 30-40% in most companies. By further categorizing your inventory into active, excess, slow moving and non-moving inventory, you can improve this quality ratio enormously - typically identifying, achieving and sustaining a 30% reduction in inventory on hand.

While Lean Thinking as a strategy will yield impressive results in WIP and inventory reduction, the results can take from 6 to 18 months to see. Using IQR as a tool for rapid inventory reduction deployment, expect to see step change results in 3-6 months. Contact us for more details.

Norm

www.normanbain.com

Lean Resource Guide

Confused about lean concepts or terminology? Then visit the NBI knowledge center or our management library. Our on-line education and continual learning resource guide!

Norm www.normanbain.com

Norm www.normanbain.com

Friday, August 21, 2009

Lean waste elimination fails to hit the bottom line numbers

Many companies, embracing the concepts of lean thinking, hear the urging to 'Just do it', in the spirit of the leaders and pioneers of the Toyota Production System. They then excitedly delve into the transformation process. They stage a kickoff meeting to share their passion, pick something important and start removing waste quickly to capitalize on that “low hanging fruit”.

The target area becomes a beehive of activity, kaizen events, continuous improvement blitzes, 5S initiatives and production tracking boards. People get engaged in the process improvements and the staff gains some hope that finally the company is listening to what they are saying.

Yet flow through the facility does not consistently improve, the mounds of in process inventory do not reduce, and expediting hot orders remains the norm. No cost savings reach the bottom line, there is no demonstrable service and quality improvement for the customer. The improvements are not sustainable. Processes drift back to the old ways of doing things.

So management reaches the conclusion that lean does not work in this environment. We are “different” and the principals must not apply in this industry. We cannot demonstrate a return on our investment.

This lean offensive with its disappointing result drifts off as another abandoned program.

So why does this happen? Why do the concepts of lean, that seem to be such common sense, not work when we apply them? How can so much information be readily available about this approach to process improvement, yet it is so incredibly difficult to implement with concrete demonstrable results?

Click here to read the rest of this article and explore the answer to this all too common dilemma

Norm

www.normanbain.com

The target area becomes a beehive of activity, kaizen events, continuous improvement blitzes, 5S initiatives and production tracking boards. People get engaged in the process improvements and the staff gains some hope that finally the company is listening to what they are saying.

Yet flow through the facility does not consistently improve, the mounds of in process inventory do not reduce, and expediting hot orders remains the norm. No cost savings reach the bottom line, there is no demonstrable service and quality improvement for the customer. The improvements are not sustainable. Processes drift back to the old ways of doing things.

So management reaches the conclusion that lean does not work in this environment. We are “different” and the principals must not apply in this industry. We cannot demonstrate a return on our investment.

This lean offensive with its disappointing result drifts off as another abandoned program.

So why does this happen? Why do the concepts of lean, that seem to be such common sense, not work when we apply them? How can so much information be readily available about this approach to process improvement, yet it is so incredibly difficult to implement with concrete demonstrable results?

Click here to read the rest of this article and explore the answer to this all too common dilemma

Norm

www.normanbain.com

Labels:

Change Management,

Lean,

Lean Results,

Lean Thinking

Tuesday, August 18, 2009

Creating a Sense of Urgency Among Employees

John Ryan of the Center for Creative Leadership posted an article this week on Creating a Sense of Urgency Among Employees.

In it he talks about:

• Don't take your foot off the gas.

• Don't hesitate to share bad news.

• Convey optimism and passion.

• Publicly praise urgent actions.

• Partner with colleagues on strategy.

Great thoughts from a great organization. Read the post here.