All businesses consist of processes. Processes for purchasing materials, receiving materials, storing materials, modifying materials, making parts, moving parts, assembling parts, packaging parts, verifying parts, shipping parts, creating invoices, receiving payments, keeping score, recruiting talent, rewarding talent, training talent ... the list as endless as the imagination and complexity of the organization.

However, many of these processes do not add value for the customer.

The customer is defined as the person who uses your product or service. Your customer may not particularly care if you have a harassment policy and have everyone trained in its application. Your customer may not see value in the time your team spends waiting for instruction or searching for tools. We can all identify several activities that, if viewed through our customers eyes, would not be considered adding value.

To be considered value added, the activity must meet three conditions; (1) it must be something that the customer would be willing to pay for, (2) it must change the “thing” as it moves through the process, and (3) it must be done right the first time. Rework in any form does not add value.

Value stream mapping looks at the flow of product through your entire process and links together the steps that add value. At each of these steps we determine who is involved involved, the time it takes, the value added time it takes, the inventory of parts and product on hand, the signals and instruction that tell us what and when to build.

A value stream map displays a picture of how material and instructions move product through a value stream. So the first step in creating a value stream map, is identifying the value stream. What product, or family of products are we trying to map?

Key things to consider; What products share common processes? Where does the value stream start and end (order entry to shipment)? Are there optional processes? Does everyone on every shift perform the tasks in the same sequence, using the same equipment and the same procedure? Have we asked the people currently doing the work if this is how they really do it today?

Once the map is complete, it will clearly show how long it takes material to flow through the value stream (our lead time) and some opportunities for improvement will become apparent.

A value stream mapping exercise typically starts with a “scoping exercise”. This exercise looks at each step in the process and identifies;

(1) What is the main activity at this step? What comes in and what goes out?

(2) How long does it take (best time, worst time, average time)?

(3) How much of that time is adding value?

(4) What materials are required, how much do we have, how much do we need?

(5) What is our cue to do work (a schedule, an empty shelf, supervisory instruction)?

(6) How long does it take to set up the equipment/job?

(7) How do we move material into the station and out of the station? What is the cue to move?

To complete the scoping exercise, someone who is familiar with the work performed at this step needs to be present.

Once we have completed the scoping exercise, others working in the area should review the result to ensure nothing was missed or overlooked.

Once each step in the value stream has been identified and documented in the scoping exercise, we can transfer this information to a value stream map. The map will present a picture of how our value steam functions and give some insight into how the process can be improved.

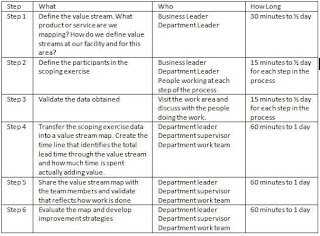

The following steps are required in value stream mapping:

The value stream mapping exercise will clearly show where problems/opportunities exist with material and communication flow through the facility. The leadership of the area along with the work team can use this information to formulate an improvement strategy to improve this flow through the value stream.

Value stream mapping is a powerful tool to provide insight to value stream throughput improvement.

Norm

www.normanbain.com

No comments:

Post a Comment